What is chemical process simulation?

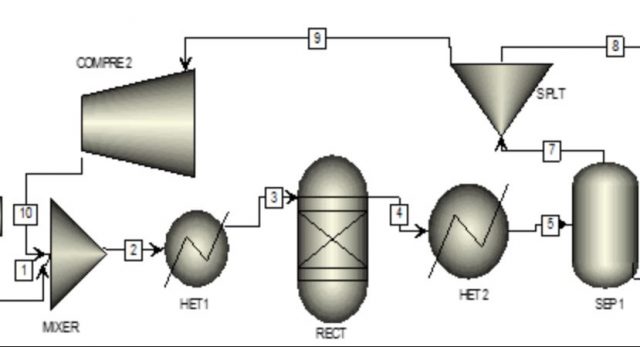

Simulation is the imitation of a process that is mostly used for the study. In order to combat the tough challenges caused by the complicated processes in the chemical study, a simulation is implemented. Chemical process simulation is the representation of a chemical process through a mathematical model that involves the calculation of mass and energy balances. This is coupled with phase equilibrium, transport, and chemical kinetics equations.

This is done to predict the behavior of a process in which some preliminary data of said process is known.

Chemical Process Simulation products

These are steady-state and plant simulation tools that help chemical engineers create optimal process designs to analyze plant operations. They help develop performance improvement strategies, monitor and optimize chemical plant operations.

Aspen Plus

It is one of the most known chemical process simulators. It offers a wide range of calculation possibilities for the optimization of safe manufacturing. It enables a steady state of dynamic petrochemical and chemical processes, including non-ideal systems.

Chemcad

This is software that includes libraries of chemical components, thermodynamic methods, and unit operations. It supports a simulation of continuous chemical processes from lab scale to full scale. It is recommended for chemical process designers and those who wish to rate existing processes.

DynoChem

This is a scale-up software system for scientists and chemical engineers working in the pharmaceutical industry. The adoption of this system is assisted by on-site training and targeted application webinars. Its tools are provided for companies to develop their own template models and implement multi-state equipment databases.

HSC Chemistry

This is an Outotec tool that is capable of carrying out thermodynamic and mineral processing calculations on a standard computer. It uses an essential software toolkit for process research, development, and digitalization. The ability of HSC Chemistry to solve real processes in industrial chemistry decreases the amount of trial and error at the R&D stage.

Types of Chemical process simulations

Steady-state process simulation

This type of chemical process simulation performs a mass and energy balance of a process in an equilibrium state independent of time. It is used to determine optimal design parameters and operating conditions of the systems.

Dynamic state process simulation

This is an extension of the steady-state process simulation. It uses derivative terms to build time dependence into the model. This means that the time-dependent description and prediction in real-time is possible!

It can be used in both online and offline fashion.

Applications of Chemical process simulations.

Advanced Simulation Library

This simulation processes data validation and reconciliation as well as real-time optimization. It also incorporates virtual sensing and predictive control.

AP Monitor.

This simulation is used in Python and MATLAB data reconciliation. It also applies dynamic simulation and non-linear predictive control.

BATCHES

This program simulates recipe-driven multiproduct and multipurpose batch processes. The simulation is applied in chemical design and scheduling.

Cycle-Tempo

This simulation program optimizes and analyzes thermodynamic systems. This helps in the production of electricity, heat, and refrigeration.

Chemical process simulation identifies and eases scaling up challenges by creating a model and solutions to chemical processes in real-time.